Assembly of Flanged Connections

Qualified assembly is extremely important to integrity & tightness of flanged connections. It is not just about applying the specified torque (prestress) during assembly. According to our philosophy, assembly should be regarded as essential step of quality control.

Depending on the requirements, the assembly tools used can range from a torque wrench to hydraulic tensioners combined with bolt force measurement.

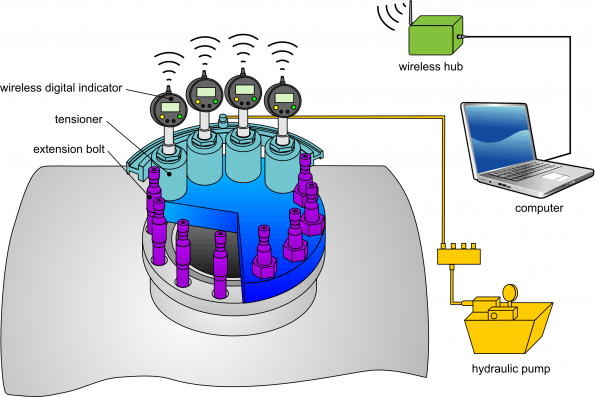

Hydraulic Tensioning

Regarding flanged joints that have to be tight under all circumstances, i.e. joints of components which are important to safety (e.g. in nuclear power plants) or flanged joints of components that contain dangerous medium, we prefer hydraulic tensioning. Compared to methods that apply torque, friction effects are of less significance consequence, and bolt torsion is very low. Furthermore, all bolts in a connection can be tightened simultaneously, thus, a complicated tightening sequence is not necessary. Using hydraulic tensioning, some elements of the joint – especially the sealing elements – are usually loaded higher than the determined prestress. This accelerates plastic deformation, and excellent seating is a result.

Bolt Force Measurement

Regarding critical joints, it is recommended to control bolt forces. The resulting levels of bolt stress and the stress distribution are monitored during assembly. ![]() has developed a variety of systems permitting comprehensive control of the tightening procedure.

has developed a variety of systems permitting comprehensive control of the tightening procedure.

![]() provides hydraulic tensioning tools for all kinds of flanged connections – individual tensioners or modules with multiple tensioners – tailored to customers needs. more...

provides hydraulic tensioning tools for all kinds of flanged connections – individual tensioners or modules with multiple tensioners – tailored to customers needs. more...

In addition to hydraulic tensioning tools, ![]() provides specially developed elongation measurement sensors to control bolt force.

provides specially developed elongation measurement sensors to control bolt force.

The bolts of the joint are equipped with internal pins. When loaded, the bolts become longer; the internal pins remain on their initial length even under load. Thus the bolt elongation as a function of load can be measured; it is proportional to the force applied – this can be calibrated.

The bolt elongation / bolt load is monitored using electronic dial extensometers with wireless data transmission to a laptop computer.

All stages of the tightening process can be documented.

Ultrasonics can be used to record the prestresses in the bolts during assembly. An ultrasonic pulse is emitted at one end of the bolt; it runs through the bolt and is reflected at the opposite end as an echo which returns to the test head. The time for the ultrasonic pulse to travel between each end of the bolt is used to measure the bolt elongation. When calibrated, this allows control of bolt forces applied.