Test Rigs for Packings

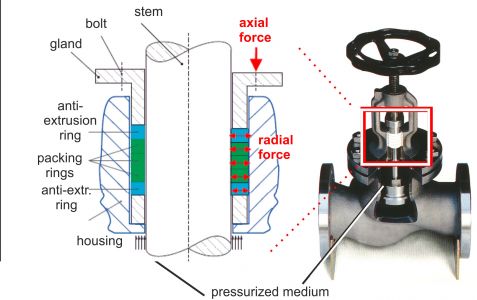

The integrity and tightness of stuffing box packings (valve stem seals) have to be safeguarded during the entire life cycle.

The first step to achieve this is done by selecting the proper materials. Regarding the selection of the most suitable packing material, material characteristics have to be known in detail. Additionally, material characteristics are required to determine the prestress which has to be applied during assembly (tightening torque) and for tightness analysis as well as for the calculation of the friction forces.

Characteristic material properties of packing materials are:

- deformation behavior

- tightness behavior

- friction behavior

and:

- resistance against wear

- resistance against corrosion

- long-term performance

![]() has developed test rigs for all relevant characteristics of stuffing box packings. These test rigs are ideal tools for product development and quality control for packing material developers and for end users who operate a high number of valves in their plants.

has developed test rigs for all relevant characteristics of stuffing box packings. These test rigs are ideal tools for product development and quality control for packing material developers and for end users who operate a high number of valves in their plants.

Additionally, ![]() provides testing services to all parts of industry in our lab.

provides testing services to all parts of industry in our lab.

The test rig TEMES stb.freak simulates a rising or rising-rotation stem valve.

The test rig TEMES stb.freak provides:

- friction tests at ambient temperature and at elevated temperatures

- long-term tests

- leakage tests

Using the test rig TEMES stb.freak,

- deformation behavior

- tightness behavior

- friction behavior

- long-term behavior

of stuffing box packings can be determined.

Valve packing type tests, e.g. according API 622, can be performed.

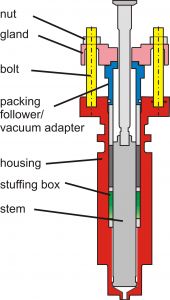

The test rig TEMES stb.freak consists of a mechanical test device (idealized body and stem), a control cabinet, a cooling unit, a leakage unit, a computer and a monitor. Optionally, a mass spectrometer can be applied to measure leakage.

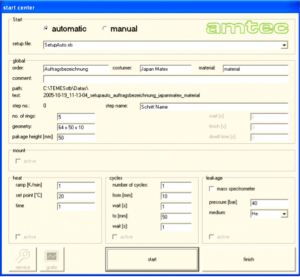

The test rig can be controlled both manually and fully automatically — a major advantage concerning long test periods.