Gasket Testing

in our Accredited Test Laboratory

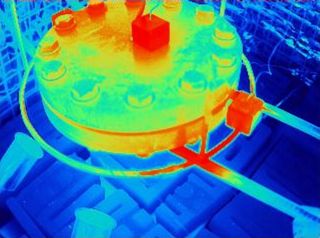

![]() does not only sell test equipment; we use every single test rig shown above in our test laboratory, too. Actually, gasket testing is carried out mainly in the well equipped test laboratory of our European branch.This lab is

does not only sell test equipment; we use every single test rig shown above in our test laboratory, too. Actually, gasket testing is carried out mainly in the well equipped test laboratory of our European branch.This lab is

- accredited by DAkkS (member of the International Laboratory Accreditation Cooperation ILAC)

and the quality management is certified according

- ISO 9001.

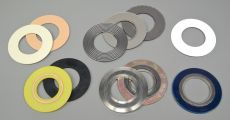

The latest testing technology is applied to determine the deformation and sealing characteristics of gaskets as specified e.g. in

- American standards

- European standards

- user / industry specifications.

Standards for gasket testing

Gasket testing is performed according to industry standards, such as:

|

|

The complete range of services provided by our test laboratory is available as a download. Do not hesitate to contact us for a quotation.

Standard Tests

These standardized procedures provide the determination of gasket characteristics in:

- compression tests

- leakage tests

- compressive creep tests

- creep relaxation tests

at room temperature or elevated temperatures (up to 400 °C / 750 °F) as well as under internal pressure (up to 200 bar / 2,900 psi).

Special Tests

... for developing new gasket materials or screening tests according to special company specifications (e.g. petrochemical companies like Shell, Total, ...).

Fire-safe testing or blow-out testing is also possible in our laboratory.

User defined applications have been realized, too, e.g. tests for high-temperature applications up to 800 °C / 1,470 °F.

Tell us about your specific needs – our engineers will work out a solution for you.