Tightening procedure TEMES stb.ctrl

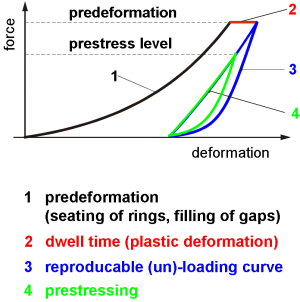

Following the amtec TEMES stb.ctrl procedure the tightening of stuffing box packings is performed in two steps: pre-deformation (plastic deformation) and pre-stressing (i.e. application of assembly stress). The loads applied during pre-deformation can be significantly higher (room temperature stress limits) than those of pre-stressing (operation temperature stress limits have to be regarded and –more relevant- friction has to be minimized).

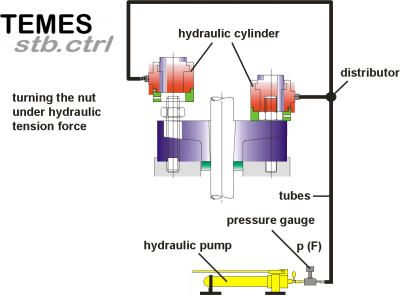

Hydraulic tensioners are ideal tools to prestress stuffing boxes. Using hydraulic tensioners, all bolts of the gland can be prestressed at the same time and the packing deformation is uniform. Furthermore hydraulic prestressing (advanced two step procedure: high pre-deformation for good seating, final pre-stress level below pre-deformation value) is less time consuming than other methods.

Compact tensioners are tailored to fit on almost every construction; a small set of different spanners is enough to cover quite a number of different valves.

Regarding important valves the patented ![]() procedure TEMES stb.ctrl is recommended. During pre-stressing, the force / deformation relation is recorded. After appropriate seating the force / deformation relation is reproducible.

procedure TEMES stb.ctrl is recommended. During pre-stressing, the force / deformation relation is recorded. After appropriate seating the force / deformation relation is reproducible.

Thus a highly accurate pre-stressing is available, with a protocol output in the end, if necessary.