Assembly

Assembly is a very important step to achieve the desired tightness and function of stuffing box stem seals.

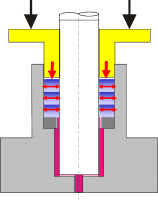

During assembly, a good seating of the packing has to first be reached. This is realized by plastic deformation of the packing rings. Existing gaps (between stem and packing / packing and housing / between the rings) have to be filled and internal leakage paths have to be closed. This process is accelerated with increased load.

After this pre-deformation, a given assembly stress value (tightening torque) has to be applied. Usually, the packing is compressed axially using a gland and bolts; the main tightening surfaces are between stem and packing / packing and housing. Therefore, regarding tightness, a sufficient radial force (better stated: radial stress) has to be maintained during every state of operation.

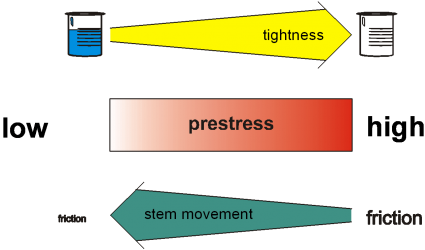

On the other side radial force, / stress induces friction between the stem and packing. For proper function of a valve, limited friction is essential.

As a consequence, tightening of stuffing box packings during assembly is a kind of optimization task: Regarding tightness the assembly stress value has to be high; regarding friction is has to be minimized.

Reliable assembly of stuffing box packings is challenging; thorough preparation is needed as well as skilled personnel.

The tightening procedure has to meet the performance demands. If the demands are high the ![]() TEMES stb.ctrl procedure is an option to consider.

TEMES stb.ctrl procedure is an option to consider.